Lab & Equipment

Laboratory Temperature & Environmental Monitoring System

Digital and automated monitoring of lab freezers, refrigerators, ULT freezers, cryogenic storage and shippers, and incubators is essential for maintaining sample integrity. Laboratory temperature and environmental monitoring systems—whether ready-to-use or custom-configured—ensure precise analysis, full traceability, and global compliance.

- Tailored to meet specific SOPs and quality standards

- Suitable for biotech startups, major research universities, and large life science or pharmaceutical centers with multiple labs and facilities

- Calibrated to ISO 9001 and ISO 17025 standards

Temperature Data Loggers and Monitoring for Pharma

Maintaining precise temperature and humidity control is a top priority in today's advanced laboratories, biotech centers and life science research facilities. The highest quality and data integrity must be ensured to protect valuable pharmaceuticals, irreplaceable biological specimens and priceless research.

-

R&D Labs

-

Medical/Clinical

-

Biological/Biosafety

-

Biomedical

-

AG/Crop Science

Research & Development Labs

Empower your R&D lab with monitoring solutions designed for innovation. ELPRO integrated solutions ensure environmental integrity and data compliance, allowing your researchers to focus on breakthrough discoveries rather than regulatory concerns.

- Preserve sample integrity

- Maintain GxP compliance

- Accelerate time-to-market with intelligent automation

Medical/Clinical

Ensure patient care with precision environmental monitoring for your clinical or medical laboratory. ELPRO integrated solutions safeguard critical samples while automating compliance documentation, reducing manual workload and minimizing error risk.

- Maintain data integrity, meet regulatory requirements

- Focus on what matters most

- Deliver accurate, timely results for better patient outcomes

Biological/Biosafety

Safeguard both research integrity and personnel. From high-containment environments to delicate biological specimens, ELPRO systems provide continuous oversight of critical parameters and containment data integrity while maintaining strict regulatory compliance.

- Maintain precise conditions for cultures

- Automate documentation

- Focus on discoveries vs. manual monitoring processes

Biomedical

Accelerate medical breakthroughs with ELPRO environmental monitoring solutions designed for biomedical innovation. our integrated systems safeguard sensitive research, streamline compliance documentation, and allow your team to focus more on life-changing discoveries.

- Protect sample integrity

- Maintain regulatory standards

- Enhance research continuity with real-time monitoring that supports your mission to improve human health.

Agricultural/Crop Science

Cultivate innovation with monitoring solutions engineered for agricultural advancement. ELPRO systems maintain optimal conditions for seed development and soil analysis while automating compliance documentation.

- Ensure research integrity

- Streamline regulatory reporting

- Focus on developing sustainable farming techniques with intelligent environmental controls

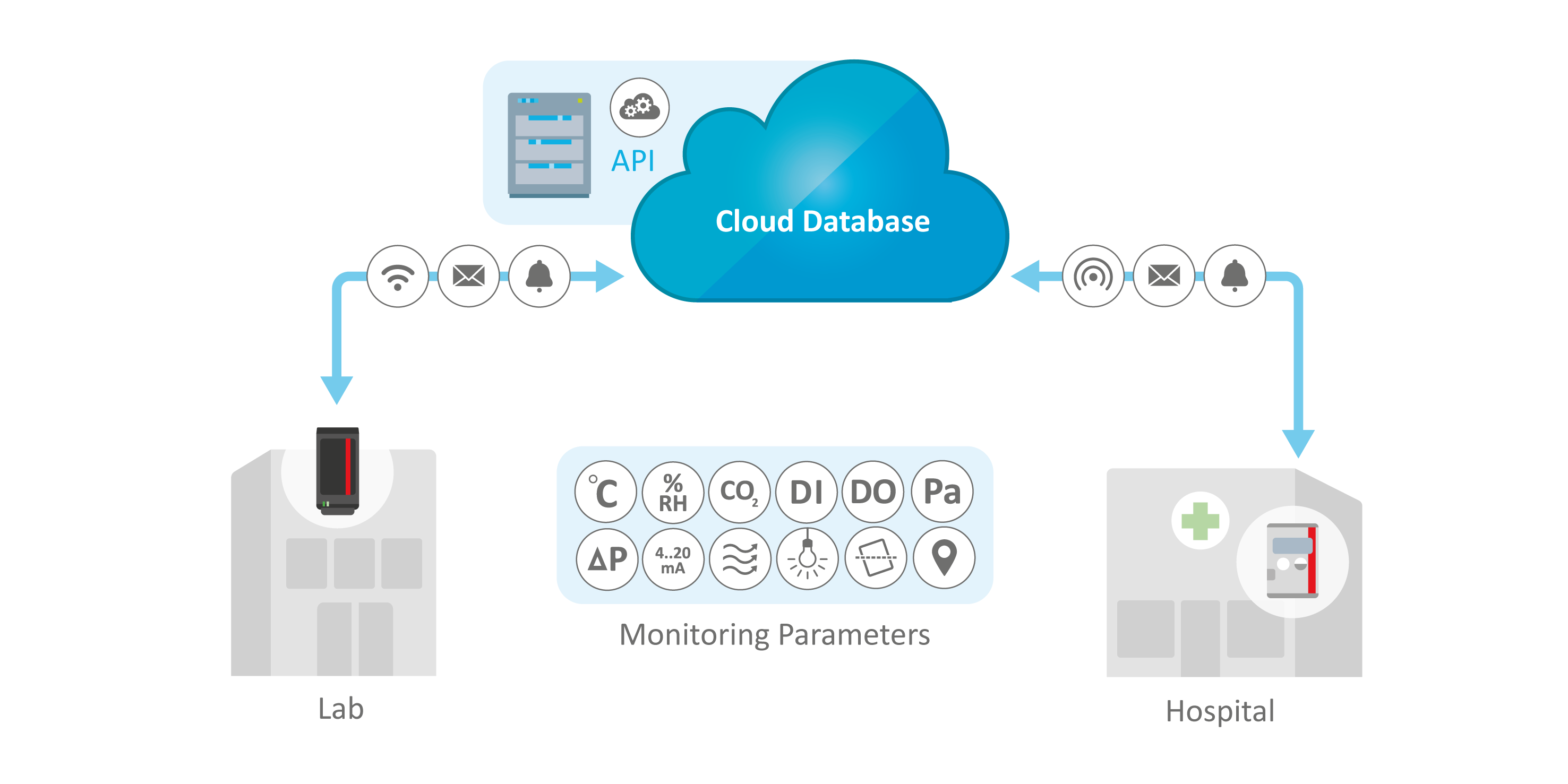

Scalable, Integrated Solution for Various Parameters

- Modular, customizable solutions with wired/wireless sensors for all critical parameters

- Available as an on-premise and software-as-a-service solution

- Intuitive software (24/7 access) with clear data visualization

- Integration into existing user management (Active Directory or Single Sign-On)

- Management of multiple locations via one solution

- Immediate alarming and notifications

- Automated reporting and analyses

- API integration for seamless data transfer to other systems

Wired Modules

- °C, %RH, 4to20mA, DI, DO

- Wired

- Stable penetration into shielded rooms

- Unlimited number of sensors

Wireless Modules

- °C, %RH, 4to20mA

- Radio frequency: 868 / 915 MHz

- Flexible positioning of sensors

- Up to 50 sensors per local radio bridge

Cellular IoT Real-Time

- °C, %RH

- LTE-M and NB-IoT (global roaming)

- IT-independent installation

- Easily scalable

Everybody’s pleased with the system. [...] Maintenance and calibration can be done as fast as possible or in due time just as we organize it.

Compliance Made Easier

Navigating global regulations and standards can be complex—but with expertise, it doesn’t have to be. Comprehensive solutions are provided to keep companies compliant and prepared for upcoming audits, ensuring smooth operations worldwide at all times. The complexity is handled, allowing focus on what matters most—your success.

Let's Talk About Monitoring Solutions for Your Lab and Equipment.

Common Questions About Monitoring Labs and Equipment

Navigating the complexities of laboratory temperature monitoring in various life science facilities? Begin by asking these important questions. Schedule a demo with an ELPRO project manager today to get more details.

How can I remotely monitor the temperature in my laboratory?

Modern temperature monitoring systems offer several effective remote solutions for laboratory environments. Wireless sensor networks can deploy temperature probes throughout your facility that transmit data to a central monitoring solution such as elproMONITOR, providing access to cloud-based dashboards from any device.

These systems feature

- customizable alarm thresholds with SMS/email notifications

- comprehensive data logging for assessments and compliance documentation

- data buffering technology for backup protection during power supply disruptions.

What is a laboratory temperature monitoring system?

A laboratory temperature monitoring system is a specialized network of sensors, data loggers, and software designed to continuously track and record temperature conditions in critical laboratory environments and equipment. These systems capture temperature data from freezers, incubators, refrigerators, stability chambers, and ambient spaces, transmitting readings to centralized platforms that enable real-time visualization, automated documentation, and immediate alerting when parameters deviate from acceptable ranges. Advanced lab monitoring systems, such as elproMONITOR, integrate with existing laboratory information management systems (LIMS), maintain audit trails for regulatory compliance, and provide secure data storage to protect the integrity of temperature-sensitive materials, research samples, and pharmaceutical products throughout their lifecycle.

How often should fridge and freezer temperatures be monitored and recorded?

For laboratory fridges and freezers containing critical samples, continuous automated monitoring is now the gold standard, recording temperatures at intervals of 5-15 minutes. While regulations typically require minimum twice-daily manual checks (8-12 hours apart), automated systems provide superior protection by capturing data every few minutes and enabling immediate response to excursions. For ultra-low temperature freezers (-80°C), more frequent monitoring (every 3-5 minutes) is advisable due to rapid temperature changes during failures. Even with automation, many labs maintain daily visual checks as a backup verification. The specific monitoring frequency should align with your risk assessment, regulatory requirements, and the stability profile of stored materials, with more frequent monitoring for highly temperature-sensitive or irreplaceable samples.

Does the FDA, EMA require temperature monitoring?

Yes, both the FDA and EMA explicitly require temperature monitoring for pharmaceutical and biologic products. The FDA mandates temperature monitoring through 21 CFR Part 211 (for drug manufacturing) and 21 CFR Part 600 (for biologics), requiring documented evidence that products are stored within specified temperature ranges. The EMA's Good Distribution Practice (GDP) guidelines (2013/C 343/01) specifically require continuous monitoring systems for all temperature-controlled environments, with recorded data maintained for at least 5 years. Both agencies expect validated monitoring systems with calibrated sensors, documented alarm responses, and comprehensive temperature mapping studies to identify potential hot/cold spots. FDA inspectors routinely check temperature records during site visits, with inadequate monitoring frequently resulting in 483 observations or warning letters, particularly when temperature excursions lack proper investigation.

What are the guidelines for laboratory temperature?

Laboratory temperature guidelines vary by application and regulatory framework.

- For general laboratories under GLP (Good Laboratory Practice), ambient temperatures should typically be maintained between 20-25 °C (68-77 °F) with a stability of ±2 °C.

- Pharmaceutical manufacturing environments under GMP (Good Manufacturing Practice) require more stringent controls, with clean rooms often maintained at 18-22 °C (64-72 °F) with ±1 °C precision and humidity at 40-60% RH.

- For sample storage, FDA and EMA guidelines mandate adherence to USP/EP/ICH specifications: room temperature (20-25 °C), refrigerated (2-8 °C), frozen (-20 °C), and ultra-low (-80 °C).

- Stability testing chambers following ICH Q1A guidelines require precise conditions (25 °C ±2 °C/60% RH ±5% or 30 °C ±2 °C/65% RH ±5%).

How do I monitor the temperature of my freezer, refrigerators, incubators and other lab equipment?

To effectively monitor lab equipment temperatures, implement a multi-tiered approach using validated monitoring systems. Install calibrated temperature probes inside each unit, positioning sensors at identified hot/cold spots from thermal mapping studies. Connect these probes to a monitoring system, such elproMONITOR, featuring continuous data logging, customizable alarm thresholds, and automated notifications via text/email when excursions occur. For critical equipment, employ redundant monitoring with independent secondary sensors. Ensure your system includes battery backup, compliant data storage, and audit trail capabilities to meet regulatory requirements. Modern systems offer cloud-based dashboards for remote access and automated report generation. For comprehensive protection, complement electronic monitoring with regular visual checks of equipment and verification that probes remain properly positioned and calibrated according to your established schedule.

Newsletter-Sign Up ELPRO News

ELPRO will use the information provided in this form to keep in touch with you and to send you updates and marketing information by e-mail.