Cryogenic Storage & Shipment

LN2 Temperature Monitoring Systems for Cryogenic Containers

In fields where preserving biological materials is vital for research and future discoveries, reliable monitoring systems help ensure consistent quality and safety—whether in large-scale cryopreservation or Wi-Fi-enabled setups. Precision monitoring solutions are specifically designed for ultra-low temperatures, supporting the use of LN2 and dry ice containers in both storage and transport.

- Measure cryogenic temperatures as low as –200°C

- Dual-sensor data loggers with external probes for cryo measurements inside containers and internal sensors for ultra-low temperatures

- Real-time monitoring with automatic alerts for excursions and LN2 level

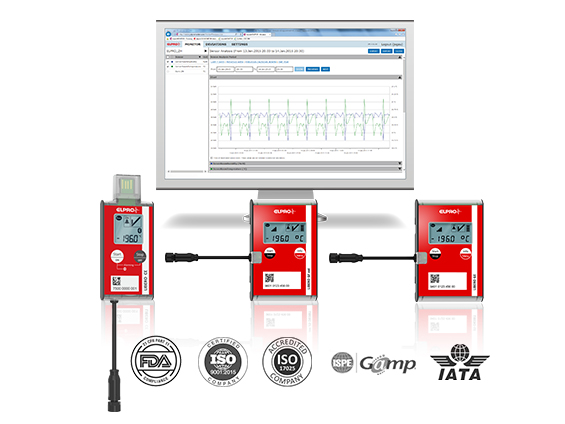

- GAMP® 5 and FDA 21 CFR Part 11 compliant and compatible with liberoMANAGER for seamless data access

Cryogenic (LN2) Temperature Monitoring Applications

Cryogenic storage and shipping applications demand precision temperature monitoring. From pharmaceutical development to human tissue preservation, ELPRO's advanced monitoring solutions are essential for protecting invaluable materials where temperature deviations can lead to catastrophic loss.

-

Cell & Gene Therapies

-

Pharmaceuticals & Vaccines

-

Biobanking & Research

Preserve Life-Saving Cellular Treatments with Advanced Alarming

Cryogenic monitoring is essential for maintaining the viability of cell and gene therapies throughout storage and transport. ELPRO's monitoring solutions ensure these highly personalized, irreplaceable treatments remain at optimal temperatures, protecting their efficacy and preventing devastating losses of therapies that often represent a patient's last treatment option.

Secure Vaccine Efficacy at Every Temperature-Critical Stage

Critical pharmaceuticals and advanced vaccines require ultra-cold or cryogenic storage to maintain molecular integrity and potency. ELPRO's monitoring systems ensure these vital medical resources remain at precise temperatures throughout the entire cold chain, providing auditable documentation of storage conditions and safeguarding public health resources.

Monitor and Protect Irreplaceable Specimens for the Future

Research facilities and biobanks rely on cryogenic monitoring to safeguard invaluable biological specimens collected over decades. These biological samples often include tissues, cells and genetic material that are critical to ongoing and future research projects. ELPRO's systems provide continuous temperature verification and alerting for these irreplaceable samples, ensuring research integrity by maintaining the stringent conditions required for preservation.

Benefits of Continuous LN2 Monitoring for Research and Healthcare

Advanced Temperature Data Loggers and Monitoring Solutions for Cryogenic Applications

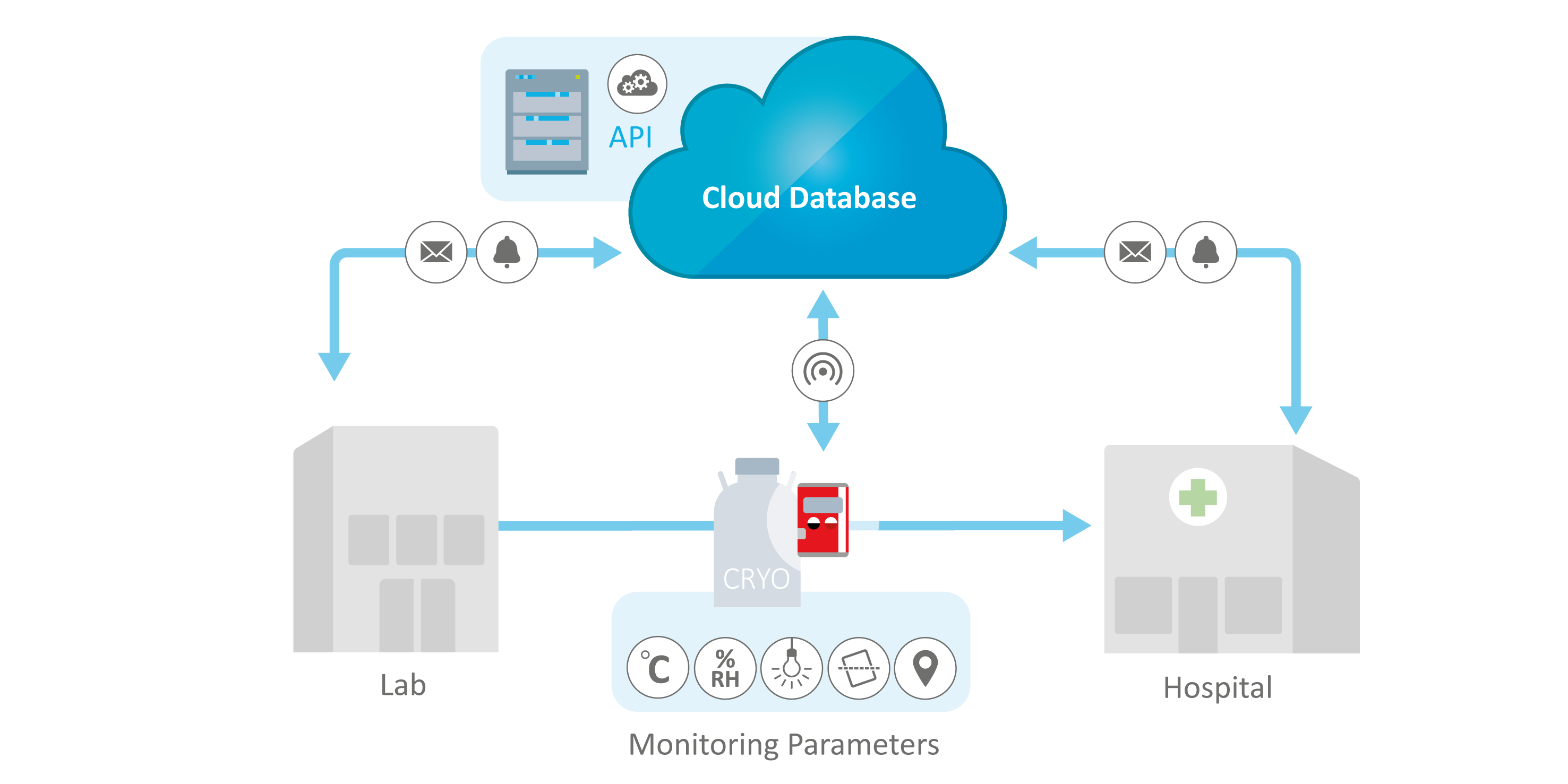

ELPRO’s complete cryogenic monitoring system combines precision data loggers with powerful cloud-based software. Designed for use with LN2 and dry ice, this integrated solution protects your most sensitive biological materials in storage and in transit.

- Accurate cryo and ambient measurements, down to -200 °C

- Cellular IoT real-time data loggers with location tracking and PDF/Bluetooth® readouts

- Secure installation on any cryo container

- Real-time alarms and notifications for immediate response

- Intuitive software with clear data visualization

- Automated reporting for compliance confidence

- API integration for seamless data transfer to other systems

Ultra-Low & Cryo

- Temperature

- Range: -200 °C to +400 °C

- Strong, robust M8 connector

- USB or Bluetooth® connection

- Automated read-out of data or PDF

- Alkaline battery—IATA-compliant

Dry-Ice

- Temperature and Position

-

Probe: -200 °C to +400 °C;

Internal sensor: 0 °C to +55 °C - Cellular IoT real-time

-

Real-time data generation and alarming

- Alkaline battery—IATA-compliant

Frozen

- Temperature and Position

- Probe: -200 °C to +400 °C;

Internal sensor: -35°C to +55 °C - Cellular IoT real-time

-

Real-time data generation and alarming

- Lithium battery

Professional Installation for Advanced Container and Tank Monitoring

Rely on our experts to install and calibrate ELPRO temperature monitoring kits to ISO 9001 and ISO 17025 quality standards on your new or used cryo containers. Our technicians have experience to install the kit on all leading brands of cryo containers. The kit and services includes:

- Quality inspection and cleaning of cryo shipper lids and parts

- Temperature data logger (configured to your exact specifications)

- State-of-the-art external sensor/probe with connector

- Stainless steel mounting bracket (optional lockable)

- Calibration points according to your specifications

- Calibration certificates (manufacturing calibration or ISO 17025)

- Guaranteed compliance

The ability to monitor two temperature ranges with the internal and external sensor is especially handy in some situations, such as during transport of stem cells.

Compliance Made Easier

Navigating global regulations and standards can be complex—but with expertise, it doesn’t have to be. Comprehensive solutions are provided to keep companies compliant and prepared for upcoming audits, ensuring smooth operations worldwide at all times. The complexity is handled, allowing focus on what matters most—your success.

Let's Talk Cryogenics. Contact Us Today.

Common Questions About Cryo Monitoring Solutions

Cryogenic storage and transport involve unique challenges that require precision, compliance and reliability—especially when dealing with sensitive pharmaceutical and biotech materials. Whether you're managing LN2 shippers or ultra-low temperature storage, ELPRO’s cryogenic monitoring solutions are designed to support your needs. Explore the answers to common questions below to learn more about how to protect your products and stay compliant in ultra-cold environments.

What does LN2 mean?

LN2 stands for liquid nitrogen. It is nitrogen in a liquid state at an extremely low temperature of -196 °C. LN2 is commonly used in cryogenic storage and transport applications, especially in pharmaceuticals and life sciences, to preserve sensitive materials like stem cells, vaccines and biologics.

What do I need to know about handling liquid nitrogen safely?

Liquid nitrogen (LN₂) is much colder than dry ice, with a temperature of –196 °C, and must be handled with extreme care. Only liquid helium (–269 °C, 4 K), used in superconducting magnets and ultra-low-temperature research, and certain other cryogenic liquids like solid neon or hydrogen can reach temperatures lower than liquid nitrogen, though these are much less commonly used.

When handling liquid nitrogen, always follow these safety guidelines:

- Personal protection: Wear cryogenic gloves, a face shield, long sleeves, and closed shoes. Never touch LN₂ or cold surfaces with bare skin — contact can cause instant frostbite.

- Ventilation: Use LN₂ only in well-ventilated areas. As nitrogen evaporates, it displaces oxygen and can cause suffocation without warning.

- Handling and transport: Use only approved, vented containers. Never seal LN₂ in a closed vessel — pressure buildup can cause an explosion.

- Filling procedures: Pour slowly to reduce splashing and thermal shock. Keep a safe distance.

- Storage: Keep containers upright and secure to prevent tipping. Avoid confined spaces.

- Training: Only trained personnel should handle LN₂. Report any spills, equipment damage, or safety incidents immediately.

Remember: LN₂ looks harmless, but improper handling can lead to serious injuries or oxygen depletion. Always follow safety instructions and use the correct protective equipment.

How do you measure LN2?

LN2 levels are typically measured using specialized level sensors or weight-based systems inside the cryogenic storage tank. These sensors provide real-time data and can trigger alarms when levels drop too low, helping ensure a continuous, stable environment for sensitive materials. Leveraging advanced technology such as wireless sensors and cloud-based monitoring systems can further enhance oversight, allowing facility managers and technicians to access data remotely and respond swiftly to any irregularities.

Additionally, regular maintenance of the sensors and periodic calibration are recommended practices to maintain their accuracy and reliability, which ultimately protects the integrity of stored biological materials.

What does cryogenic status mean?

Cryogenic status refers to the current condition or performance of equipment used in cryogenic environments—typically at temperatures below -150 °C. This includes temperature readings, LN2 levels, alarm states, and system integrity to ensure the safety of stored or transported materials.

What is the liquid nitrogen level alarm?

A liquid nitrogen (LN2) level alarm is a safety feature that alerts users when the LN2 inside a cryogenic container drops below a set threshold. This prevents the temperature from rising and compromising product integrity, providing an early warning before a critical failure occurs.

What is the liquid nitrogen alarm system?

A liquid nitrogen alarm system is a comprehensive setup that monitors LN2 levels, temperatures, and equipment status. It includes sensors and data loggers that trigger visual, audible, or remote alarms if conditions fall outside safe parameters—ensuring constant oversight and protection.

What are the rules for liquid nitrogen storage tanks?

Storage tanks for LN2 must follow strict safety and regulatory guidelines. These include proper ventilation, secure placement away from heat sources, routine inspections, and compliance with GxP and local safety regulations. Tanks should also be equipped with pressure relief valves and monitored continuously to prevent hazards such as over-pressurization or leaks.

Why is professional installation of cryogenic sensors important?

Incorrect sensor installation can damage the probe or container lid, reduce static hold time, and lead to inaccurate readings. ELPRO offers professional installation services to ensure sensors are correctly placed and your monitoring system performs reliably from the start.

Can ELPRO loggers monitor both internal and ambient temperatures?

Yes. ELPRO’s cryogenic data loggers are equipped with an external probe to measure cryogenic temperatures inside the container (as low as -196 °C) and an internal sensor to track ambient temperatures, giving a full picture of environmental conditions.

What happens if there is an alarm event during shipment?

If an alarm is triggered—such as a temperature excursion or low LN2 level—ELPRO’s data logger stores the event. Depending on the setup, users may also receive notifications in real time. The data can be downloaded and reviewed to verify if the shipment stayed within the required temperature range.

Newsletter-Sign Up ELPRO News

ELPRO will use the information provided in this form to keep in touch with you and to send you updates and marketing information by e-mail.