GxP Mapping Services

Temperature and Humidity Mapping Services—GxP-Compliant and Reliable

Temperature and humidity mapping for pharmaceutical equipment and facilities is a global regulatory requirement. With 40 years of experience, ELPRO provides comprehensive GxP mapping services for warehouses, production areas, cleanrooms, transport boxes, ultra-low temperature freezers, climate chambers, trucks, fleets, and more.

Ensure compliance and proper system functionality with:

- Professional temperature and humidity mapping services

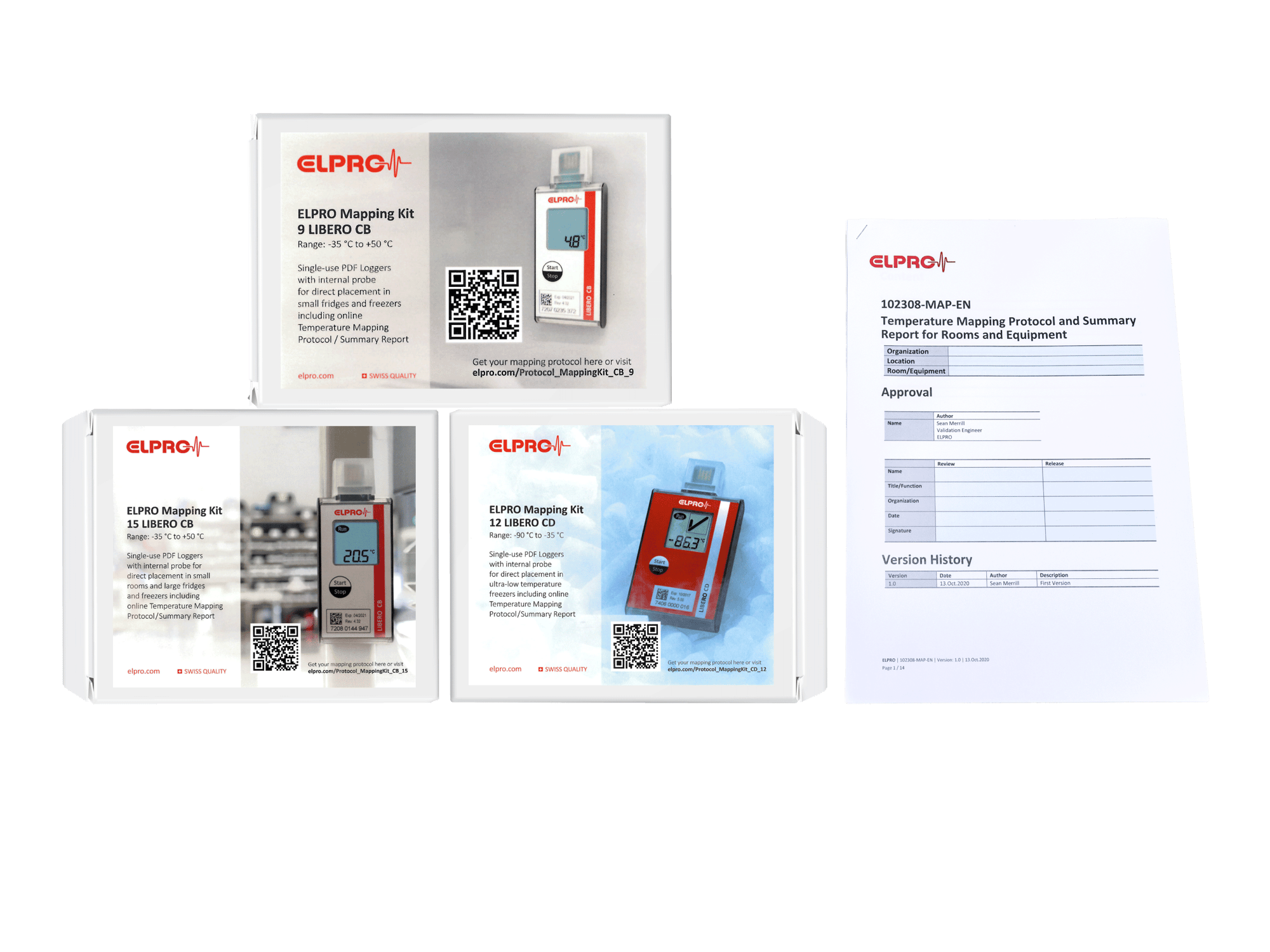

- Self-service mapping kits

- Detailed mapping data evaluation

- GxP-compliant documentation

Temperature Mapping Services—Designed to Your Needs

ELPRO provides temperature and humidity mapping services and equipment for a wide range of applications to ensure compliance and reliability. Whether you need mapping for small equipment or for larger environments, we have the expertise to support you. Our solutions also cover ultra-low temperature freezers, transport boxes, and containers, as well as trucks and entire fleets—helping you maintain precise environmental conditions across your supply chain.

We offer complete services to map your entire life science environment or provide self-service mapping kits for those who prefer to handle the process themselves. In this case, ELPRO supports you by evaluating the mapping data and finalizing the GxP-compliant report.

Refrigerators, Freezers, Incubators, Climate Cabinets

The Temperature Mapping Process—From Planning to Reporting

At ELPRO, every temperature mapping project follows a structured process to ensure quality, and reliable results:

- Planning and risk assessment

We start with detailed project planning, defining the scope, areas to be mapped, acceptance criteria, and potential risk points. - Mapping execution

Our experts place and activate calibrated data loggers to monitor temperature and humidity continuously across all critical locations. - Data analysis and reporting

After data collection, we provide a complete report with analysis, documentation, and proof of temperature and humidity measurements. The report includes tabular and graphical overview of all measuring points, deviation summaries, recommendations for corrective actions and for placement of monitoring sensors

This end-to-end approach provides you with proof that your storage and transport environment comply with regulatory requirements.— with full transparency and audit readiness.

Let ELPRO Handle the Entire Process for You

Large pharmaceutical storage and distribution facilities come with unique challenges, especially when mapping transport boxes, containers, or entire fleets. ELPRO simplifies this process with all-in-one mapping services or onsite GxP technicians to support you every step of the way—saving you time and effort on both data loggers and resources.

Our efficient remote mapping method eliminates travel costs. Using your floor plan, container layout, or network plan, we design a tailored mapping layout and prepare the data loggers. Your team places and starts them on-site, while ELPRO handles the GxP-compliant mapping report.

We offer temperature and humidity mapping using data loggers with standard production calibration or ISO 17025 calibration if required.

Benefits of Doing GxP-Compliant Temperature Mapping With Experts From ELPRO

GxP-compliant temperature mapping ensures that your storage and transport conditions meet FDA, EMA, and WHO regulatory guidelines, reducing the risk of product spoilage or quality deviations. By working with experienced experts, you benefit from professional planning, accurate execution, and reliable analysis, rather than navigating the process alone. This approach also provides clear documentation and traceable data, increasing transparency and confidence during audits and inspections.

GxP-Compliant Mappings Made Easy With the Right Mapping Equipment

You’d rather do your mapping yourself? ELPRO’s self-service mapping kits offer a great solution for independent temperature and humidity mapping in GxP environments. With pre-configured, calibrated GxP-compliant temperature measurement equipment (data loggers and sensors), a customized mapping plan, and data evaluation after completion, you can ensure compliance without relying on external technicians.

Let's Talk About Your Next GxP Mapping Project. Contact Us Today.

Seven Questions about Temperature Mappings

What is temperature mapping and why is it important?

Temperature mapping is the systematic process of measuring and documenting temperature and humidity variations within storage or transport environments, such as warehouses, cold rooms, freezers, or transport vehicles. In the pharmaceutical industry, where many products are highly sensitive to temperature fluctuations, temperature mapping is essential for ensuring that conditions consistently remain within validated ranges.

It serves several key purposes:

- Regulatory compliance: Temperature mapping helps companies meet strict pharmaceutical regulations and guidelines, including GxP requirements, by proving that storage and transport environments are suitable for sensitive products.

- Identification of risks: Mapping identifies hot and cold spots or areas of uneven air distribution in warehouses, vehicles, or equipment, which could compromise product stability.

- Quality assurance and audit readiness: The data collected forms the foundation for quality management systems, internal controls, and regulatory audits, demonstrating that products are handled safely and consistently.

Why it matters: By understanding environmental variations and controlling risks, pharmaceutical companies can protect product efficacy, patient safety, and brand integrity while maintaining compliance with international standards.

How many data loggers/sensors are needed for temperature mapping?

The number of data loggers/sensors required depends on the volume of the room or equipment.

- For a system with a volume of up to 2m³, 9 data loggers are required.

- For a system with a volume of up to 20m³, the minimum number of data loggers is 15.

- For systems with a volume exceeding this, ELPRO follows the ISPE guidelines. The ISPE specifies that data loggers must not be more than 9 meters apart.

In general, loading and inside air circulation (e.g. influence of shelves etc.) are important aspects that must be taken into account in addition to the above specifications.

How do you conduct temperature mapping?

Conducting temperature mapping involves a systematic process to assess the temperature distribution within a specific area, such as a storage room, freezer, or transport container. Here are the key steps involved in conducting temperature mapping:

1. Define objective and scope

- Determine the purpose of the mapping (e.g., regulatory compliance, product stability).

- Identify the specific area or equipment to be mapped, such as refrigerators, freezers, or larger rooms.

- Assess the temperature-sensitive products or materials within the mapped area in order to define acceptance criteria.

2. Design the mapping plan

- Develop a mapping plan that outlines the number and placement of temperature sensors or data loggers. The layout should cover all critical areas, including high-risk zones such as doors, corners, and shelves.

- Use a grid or systematic approach to ensure all areas are adequately covered. The placement of sensors should account for airflow patterns and potential hot or cold spots.

- Consider environmental factors (e.g., ambient temperature, humidity) that may affect temperature variation.

3. Select the appropriate measuring equipment (data logger)

- Choose the right type of data loggers or probes based on temperature/relative humidity range, precision, and regulatory requirements.

- Ensure that data loggers have the necessary calibration certificates, such as ISO 17025, for accuracy.

4. Place the sensors or data loggers

- Position the sensors at the identified points in the mapping plan. Depending on the environment, this could include placing loggers at varying heights (top, middle, bottom), near doors, or in areas with poor airflow.

- In larger areas, sensors may need to be placed at multiple points to capture temperature variation across the entire space.

- Document data logger placement accordingly.

5. Start the mapping process

- Activate the data loggers to begin recording temperature data over the desired mapping duration.

- Document start of mapping date and time accordingly.

6. Monitor and adjust during the mapping process

Ensure the data loggers are functioning correctly throughout the mapping period.7. Retrieve and analyze the data

- Once the mapping is complete, retrieve the data from the loggers.

- Analyze the data to identify any temperature fluctuations, hot/cold spots, and areas where temperature control may be insufficient.

8. Generate the mapping report

- Based on the analysis, create a GxP-compliant report that includes detailed temperature data, observations, and conclusions.

- The report should highlight any deviations from the required temperature range and provide recommendations for corrective actions if needed.

- Provide recommendations on the placement of data loggers for continuous monitoring.

9. Implement improvements (if necessary)

- If temperature deviations are found, consider adjusting equipment, optimizing airflow, or making changes to the storage layout.

- Re-map the area if significant changes are made to ensure compliance is maintained.

Temperature mapping is a critical process in ensuring regulatory compliance and maintaining the integrity of temperature-sensitive products. It helps identify any potential risks or inefficiencies in temperature control, allowing for timely corrective actions to ensure optimal conditions.

Which international regulations deal with temperature mapping?

Several international regulations and guidelines address temperature mapping in GxP environments to ensure compliance, product integrity, and patient safety. These include:

1. Good Manufacturing Practice (GMP) regulations

- EU GMP Annex 15 (Qualification and Validation): Requires temperature mapping for storage areas, ensuring they maintain controlled conditions.

- WHO Technical Report Series (TRS) 961, Annex 9: Provides guidelines for qualification of storage areas, including temperature mapping.

- US FDA 21 CFR Part 211 (Current Good Manufacturing Practice for Finished Pharmaceuticals): Requires environmental control and validation of storage conditions.

2. Good Distribution Practice (GDP) guidelines

- EU GDP Guidelines (2013/C 343/01): Mandate temperature mapping for warehouses, cold rooms, and transport systems to ensure proper storage conditions.

- WHO Guideline TRS961 Annex 9: Provide a framework for maintaining the quality of pharmaceutical products during storage and distribution.

- ISPE Good Practice Guide Controlled Temperature Chambers: Provides guidance on good practices for the mapping of controlled temperature chambers, warehouses, and refrigerated storage areas used to store raw material, work in progress, or finished product. It is intended to be used when specifying commissioning and qualification activities.

3. ISO standards

- ISO 17025: Specifies calibration and validation requirements for temperature mapping equipment (e.g., data loggers).

- ISO 9001: Includes quality management requirements that influence mapping procedures and documentation.

4. United States Pharmacopeia (USP)

- Chapter <1079>: Covers Good Storage and Distribution Practices for ensuring controlled conditions in pharmaceutical storage and transportation.

- Chapter <659>: Defines temperature ranges for the storage of pharmaceutical products

5. Other industry-specific regulations

- ICH Q7 (Good Manufacturing Practice for Active Pharmaceutical Ingredients): Requires proper storage conditions, making temperature mapping essential.

- MHRA Guidance (UK): Aligns with EU GDP requirements, including temperature mapping for regulated environments.

Regulations require temperature mapping to be conducted at regular intervals and whenever significant changes occur (e.g., facility modifications, new storage equipment). GxP-compliant documentation must be maintained, and mapping must follow a risk-based approach to ensure compliance with global standards.

ELPRO provides temperature mapping solutions that help meet these international regulatory requirements efficiently.

How often should temperature mapping be performed?

The frequency of temperature mapping depends on regulatory requirements, risk assessments, and operational changes. In general, it should be performed:

1. Initial qualification

- When a new storage area, equipment, or transport system is put into operation.

- After major modifications to storage areas, HVAC systems, or racking layouts.

2. Periodic re-mapping

- Verification of the necessity of a re-mapping annually or every two years

- Re-mappings depending on specifications on internal SOP.

3. After significant changes

- If new storage conditions are introduced (e.g., adding or removing equipment).

- If temperature excursions or anomalies are detected in routine monitoring.

- After facility renovations, HVAC maintenance, or system failures that could impact temperature distribution.

4. Seasonal mapping

Seasonal mappings may become necessary for storage units affected by external conditions.

By following a risk-based approach, companies can determine the appropriate mapping frequency to maintain compliance, product quality, and patient safety. ELPRO provides comprehensive temperature mapping services to help meet these requirements efficiently.

What is the difference between temperature monitoring and temperature mapping?

The main difference between temperature monitoring and temperature mapping lies in their purpose and application:

Temperature Monitoring refers to the continuous tracking of temperature in a specific location or environment over time. This process typically involves using data loggers, sensors, or real-time monitoring systems that provide ongoing data to ensure the temperature stays within the required range. Temperature monitoring is often used to maintain compliance with regulatory standards, to detect temperature excursions, and to ensure the stability of sensitive products, such as pharmaceuticals, during storage or transportation.

Temperature Mapping, on the other hand, involves a one-time or periodic process of assessing the temperature distribution across a given area. It is typically performed in larger environments, such as rooms, warehouses, or freezers, to identify potential hot or cold spots that could affect product quality or compliance. Temperature mapping creates a detailed temperature profile of the area by placing multiple sensors or data loggers in different locations to measure temperature variation within the space. The results help optimize storage conditions and inform decisions about equipment placement or operational changes.

As a result of the temperature mapping, temperature-critical locations are identified, allowing for informed recommendations on where to place continuous monitoring probes.

In summary, temperature monitoring ensures ongoing control and alerts for temperature changes, while temperature mapping provides a snapshot of temperature variation across an environment to ensure uniform conditions. Both are crucial for maintaining compliance, but mapping is typically a more detailed, one-off assessment, whereas monitoring is a continuous process.

What equipment is used for temperature mappings?

Temperature mapping in GxP environments relies on specialized equipment to ensure compliance, accuracy, and reliability.

Key equipment includes single-use or multi-use data loggers that record temperature and/or relative humidity. These data loggers are available for various temperature ranges, including ultra-low temperatures. ELPRO LIBERO data loggers, which are used for mappings, can measure temperature ranges from -200 °C to +400 °C.

All ELPRO LIBERO data loggers are calibrated prior to the mapping study in order to demonstrate linearity throughout the measuring range. Reference standards are calibrated by an ISO 17025 (2017) accredited laboratory and are therefore traceable to international standards (e.g. SCS, NIST, UKAS, DAkkS).

Read-out of the LIBERO data loggers is feasible via the USB-port for single-use devices. Multiple-use devices can also be read-out via Bluetooth.

According to WHO guidelines, a mapping data logger should measure temperature with an accuracy of max. +/- 0.5 °C. ELPRO LIBERO data loggers ensure compliance with this requirement.

Newsletter-Sign Up ELPRO News

ELPRO will use the information provided in this form to keep in touch with you and to send you updates and marketing information by e-mail.