Cold Chain Monitoring Solutions

Comprehensive Cold Chain Temperature Monitoring Solutions

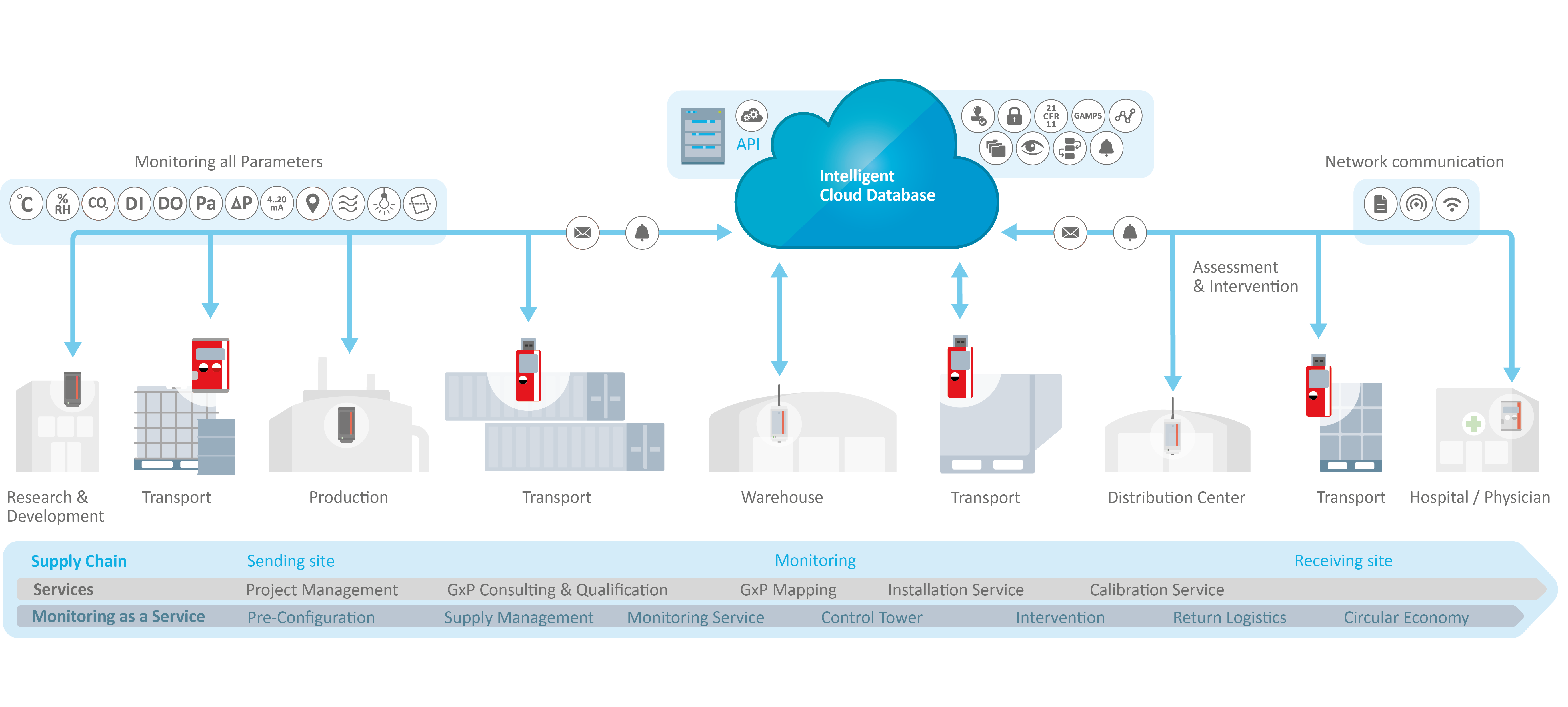

Environmental monitoring within your cold chain is complex and places great challenges on solution providers. Solutions must be tailored to the specific requirements of individual products and processes. This requires a deep understanding of a wide range of cold chain applications, appropriately calibrated and certified hardware, validated software solutions for data management, and global expert service.

ELPRO provides solutions, which:

- Ensure transparency, integrity, and compliance

- Optimize data and simplify logistics

- Enhance regulatory compliance

- Adapt quickly to industry standards

- Reduce product loss and boosts efficiency

Cold Chain Monitoring Safeguards the Quality and Integrity of your Products

Ensuring the safe and efficient transport of temperature-sensitive products requires a solution that combines reliable technology with expert support across every step of your cold chain process.

-

Digital Automation

-

Predictive Analytics

-

Transportation Visibility

-

Assessment

Streamline Processes and Reporting for Greater Efficiency

- Significantly reduce labor hours with hands-free process

- Eliminate human error and gain faster release times

- Manage large volume and complex workflows with multiple logistics providers

ELPRO's scalable, automated temperature control and data reporting systems use sustainable Bluetooth® multi-use data loggers to create the ultimate in process efficiency.

Unleash Real-Time Cold Chain Intelligence with elproPREDICT

- Combine real-time data with predictive digital analytics

- Get highly accurate, dynamic risk assessment

- See excursions before they happen

- Safeguard valuable shipments and ensure product integrity

ELPRO's cloud-based application, developed in partnership with Smart CAE, provides actionable insights, enabling proactive risk mitigation and ensuring product quality throughout the supply chain.

Helping You Deliver Hope All the Way to the Patient

- Safeguard medicines and therapies with real-time insights

- Digitally automate processes, assessments and reporting

- Eliminate blind spots and product loss

- Transform monitoring data into lane optimization

ELPRO's sustainable cold chain management solutions provide unmatched visibility for your most critical shipments, offering independent options or seamless integration into enterprise platforms.

Assessment Results in Minutes Instead of Days

- Automate stability budget management

- Track and manage complex customized workflows

- Central cloud database for analysis and trending

- Easily scale and manage simple or complex mixed-load deliveries

ELPRO's GDP-compliant temperature monitoring systems enable you to make fast, informed decisions that protect product quality, data integrity, and reducing operational costs.

Automate your Cold Chain Monitoring: From Clinical to Commercial Supply Chains

- Data loggers (USB/PDF, Bluetooth®, Real-Time) for every pharma application

- Customizable workflows to meet unique operational requirements and SOP

- Automated assessments for faster product release times, including software-based alarming for mixed-load deliveries

- API integration for seamless data transfer to other systems

- Automated reporting and clear data visualization for more informed decision-making

- Maximum data security

LIBERO Data Loggers: Uncompromising Cold Chain Data Security

- The industry's most comprehensive and versatile portfolio of cold chain data logging devices

- Sustainable single- and multi-use (Bluetooth®) PDF data loggers or real-time data loggers connected to mobile public networks

- Use as independent data loggers with PDF read-out and reporting or integrate with cloud database software to streamline processe

Single-Use USB

- Temperature

- Automated PDF report generation

- USB connection

Multi-Use Bluetooth®

- Temperature and humidity

- USB or Bluetooth® connection

- Automated read-out of data or PDF

Cellular IoT Real-Time

- Temperature, humidity and position

- Real-time data generation and alarming

- Single-Use / Multi-Use

The highly resilient project team was willing to make changes and adaptions where necessary, but perseveringly kept the initial goal in mind. They went through the process step by step. At the end, they reached the top of the mountain, a real accomplishment.

Compliance Made Easier

Navigating global regulations and standards can be complex—but with expertise, it doesn’t have to be. Comprehensive solutions are provided to keep companies compliant and prepared for upcoming audits, ensuring smooth operations worldwide at all times. The complexity is handled, allowing focus on what matters most—your success.

Let's Talk Cold Chain Efficiency. Contact Us Today.

7 Common Questions About Cold Chain Monitoring

What is cold chain monitoring?

Cold chain monitoring refers to the process of continuously tracking and managing temperature-sensitive products as they move through the supply chain. This is crucial for industries like pharmaceuticals, biotechnology, food, and chemicals, where maintaining specific temperature conditions ensures product integrity, safety, and regulatory compliance.

Why is cold chain monitoring critical?

Cold chain monitoring is crucial for preserving product quality and safety, particularly for pharmaceuticals and perishables like vaccines that require specific temperature conditions. It prevents health risks from spoiled products, avoids economic losses from spoilage, ensures regulatory compliance, and supports sustainability by reducing waste and minimizing environmental impact.

What technologies are used in cold chain monitoring?

Cold Chain monitoring uses technologies like IoT sensors for real-time data on temperature and humidity, enhancing precision and response times. AI-powered analytics help anticipate disruptions, optimizing cold chain efficiency. Advanced monitoring devices maintain climate conditions for pharmaceuticals and perishables. These systems provide continuous visibility, ensuring product safety and regulatory compliance, transforming global cold chain logistics.

How can companies improve their cold chain monitoring?

To improve cold chain monitoring, companies should adopt a multidimensional approach. Key steps include investing in IoT sensors for real-time data, conducting regular staff training on industry practices, and using data analytics for insights and predictive analysis. Robust risk management plans are essential for structured responses to anomalies. Technology collaborations offer access to tailored innovations. Prioritizing sustainability enhances efficiency and reduces environmental impact.

What regulatory standards govern cold chain monitoring?

How can cold chain monitoring enhance sustainability goals?

The future of cold chain monitoring focuses on sustainability, incorporating energy-efficient technologies and renewable energy sources to reduce environmental impact. Advanced models optimize energy use, and circular design principles promote recycling and waste reduction. Carbon footprint tracking is vital for companies to measure and lower their environmental impact.