Warehouse & Cold Room

Temperature and Humidity Monitoring in Warehouses and Cold Rooms

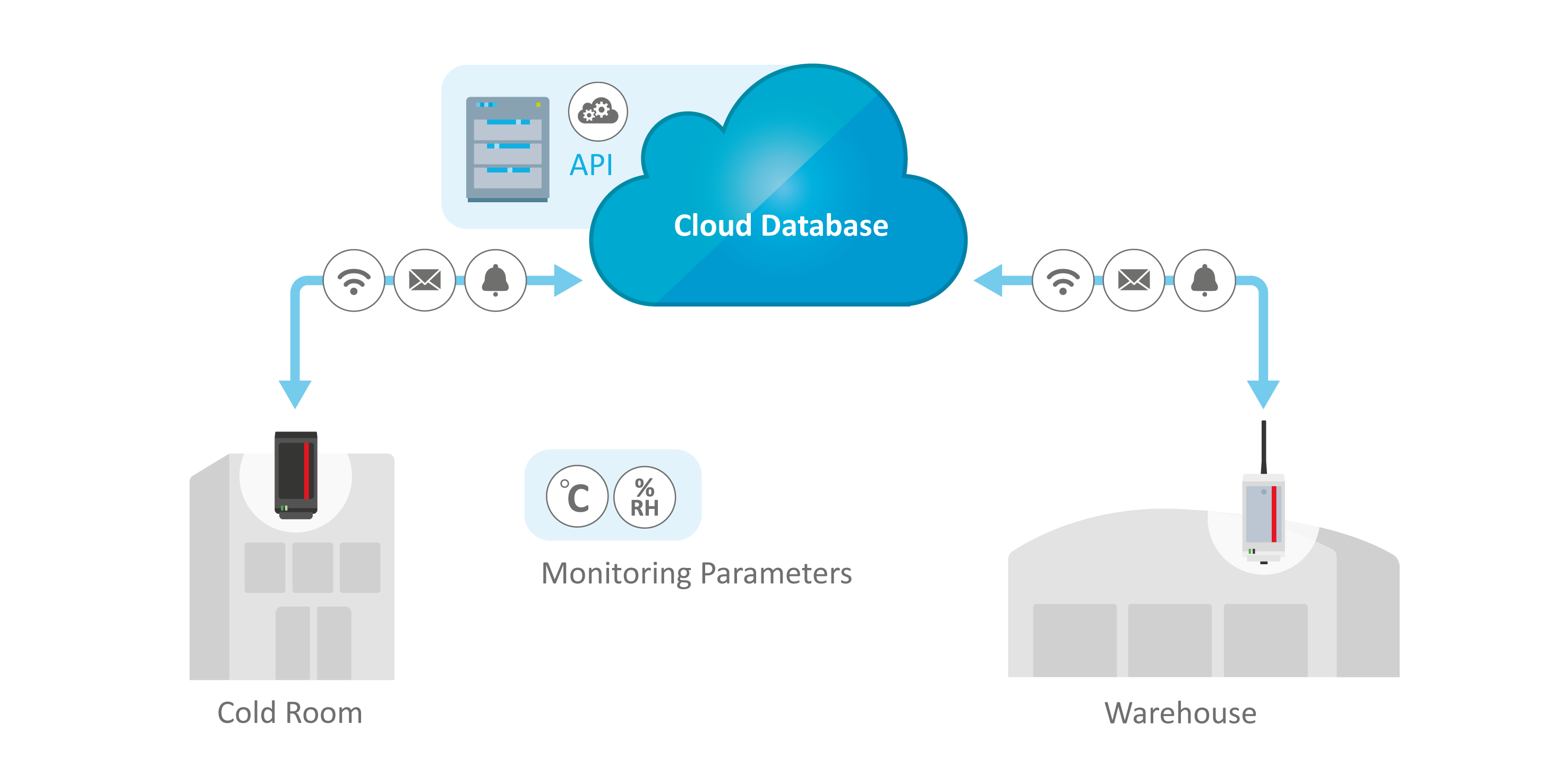

Regulated warehouse and storage facilities require more than basic monitoring. Whether for small storage rooms, large warehouses, or specialized cold rooms, maintaining optimal conditions is essential to ensure the quality and safety of stored goods. Temperature monitoring systems with advanced technologies improve control and strengthens compliance and reliability.

- Scalable environmental monitoring solutions

- Intelligent ecosystem where each sensor delivers actionable insights

- Real-time alerts to detect and prevent potential deviations

- Automation solution for device detection and bulk processing to reduce labor, minimize errors, and accelerate product release.

Optimizing Your Warehouse Temperature Monitoring System

Enhancing and fine-tuning your warehouse temperature monitoring system is crucial for ensuring optimal conditions in various environments, including small storage rooms, expansive warehouses, and specialized cold rooms. This process involves implementing advanced technologies and strategies to maintain precise temperature control, which is essential for preserving the quality and safety of stored goods.

-

Small Storage Rooms

-

Warehouses & Cold Rooms

-

Complex IntraLogistics

Smart Solutions for Smaller Spaces

In small spaces like supply closets and storage rooms, every square foot counts—and so does every data point. Precision monitoring solutions by ELPRO are essential for maintaining temperature and humidity balance crucial for product integrity.

- Effortlessly track environmental shifts

- Protect product stability, supplies and devices

- Get real-time alerts, detailed reporting, and ensure compliance

Precision Temperature Control at Scale

- Independent systems or integrated enterprise solutions

- Track temperature and humidity across every climate zone

- Seamless visibility and control

- Real-time alerts, and automated compliance reporting to protect your valuable inventory 24/7

Distributed infrastructure. Granular control.

When your operation spans millions of cubic feet and multiple locations, ELPRO environmental monitoring solutions empower you to think big. Because managing a facility of this scale isn't just about collecting data – it's about transforming it into actionable intelligence.

- Seamlessly orchestrate thousands of sensors over every corner of your operation.

- From ambient warehouses or cold rooms to freezer farms and cryogenic storage

Superior Environmental Control for Various Parameters

Hardware and software solutions from ELPRO support reliable monitoring of pharma warehouses and cold rooms. Designed to meet strict regulatory requirements, they ensure consistent environmental control and enable faster, more informed decision.

- Modular, customizable solutions with wired/wireless sensors for all critical parameters

- Available as an on-premise and software-as-a-service solution

- Intuitive software (24/7 access) with clear data visualization

- Integration into existing user management (Active Directory or Single Sign-On)

- Management of multiple locations via one solution

- Immidiate alarming and notifications

- Automated reporting and analyses

- API integration for seamless data transfer to other systems

Wired Modules

- °C, %RH, 4to20mA, DI, DO

- Wired

- Stable penetration into shielded rooms

- Unlimited number of sensors

Wireless Modules

- °C, %RH, 4to20mA

- Radio frequency: 868 / 915 MHz

- Flexible positioning of sensors

- Up to 50 sensors per local radio bridge

Cellular IoT Real-Time

- °C, %RH

- LTE-M and NB-IoT (global roaming)

- IT-independent installation

- Easily scalable

Simplified, Hands-Free Cold Chain Monitoring

- LIBERO Cx BLE multi-use Bluetooth® data loggers

- Automated device detection in multiple box types

- Bulk processing of individual box units (on pallet)

- Significantly reduce labor hours and human error

- Quicker product releases

- Automated hands-free reporting

Of course, ELPRO’s reputation also inspired confidence in this regard, and even more so the scalability of the system. [...] We can easily introduce the monitoring system to other sites or building areas. Exactly at the speed and with the functionalities that fit our growth and our requirements.

Compliance Made Easier

Navigating global regulations and standards can be complex—but with expertise, it doesn’t have to be. Comprehensive solutions are provided to keep companies compliant and prepared for upcoming audits, ensuring smooth operations worldwide at all times. The complexity is handled, allowing focus on what matters most—your success.

Got Facilities? Let's Talk Temperature Control.

Common Questions About Monitoring Warehouses and Cold Rooms

Whether GMP, GDP, or HACCP, cold rooms and warehouses and storage facilities must be monitored by an independent monitoring system—regardless of whether APIs, pharmaceuticals, medical devices, chemicals, or food/beverage products are involved. During the qualification of the room, monitoring points for temperature and relative humidity are identified. To select the right monitoring solution for your warehouses, or storage facilities, begin by asking the following questions:Is it a single storage room, multiple rooms, or warehouses?

Understanding your storage footprint is crucial for designing the right monitoring solution. Whether you're managing a single cold room, multiple temperature-controlled spaces, or expansive warehouse facilities, our system scales intelligently to match your needs. Our platform is architected to handle everything from focused monitoring of individual storage rooms to comprehensive oversight of complex facilities with multiple temperature zones. Start with what you need today, then seamlessly expand as your operation grows. Many of our clients begin with monitoring a single critical storage area, then expand their coverage as they experience the benefits of automated environmental monitoring. What matters isn't the size of your space—it's protecting what's inside it.

Are all storage locations in the same place or distributed across many locations?

Our environmental monitoring platform is designed to handle both centralized and distributed storage operations with equal precision. Whether your temperature-controlled spaces are all under one roof or spread across multiple facilities worldwide, our system provides seamless visibility and control through a single, unified interface. For distributed operations, our cloud-based architecture ensures you maintain the same level of oversight and compliance across all locations—from a local campus with multiple buildings to global facilities spanning different time zones. Each site becomes part of your connected monitoring ecosystem, with customizable alerts, role-based access, and automated reporting that can be managed either centrally or by local teams. Because whether your storage locations are next door to each other or continents apart, your environmental monitoring should feel just as immediate and responsive.

Do mobile warehouses and intralogistics also need to be monitored?

Absolutely – mobile storage and intralogistics are critical links in your temperature-controlled supply chain that demand the same rigorous monitoring as fixed facilities. Our solution extends environmental monitoring to mobile cold storage units, refrigerated trucks, and temporary storage areas with the same enterprise-grade precision you expect in permanent facilities. Whether you're managing mobile clean rooms, temporary cold storage during facility expansion, or temperature-controlled transport between warehouse zones, our wireless sensors and mobile-optimized platform ensure continuous monitoring and compliance. Because your products require perfect conditions whether they're stationary or in motion, our system moves with your inventory, maintaining an unbroken chain of environmental documentation from dock to destination.

Is local visual/acoustic alerting more important or central 24/7 alerting via email & SMS?

The most robust environmental monitoring strategy combines both immediate local alerts and comprehensive remote notification systems—because different situations demand different responses. Local visual and acoustic alerts are crucial for on-site personnel to respond instantly to environmental excursions, especially in critical storage areas where immediate action can prevent product loss. However, in today's connected operations, central 24/7 alerting via email and SMS is equally vital, ensuring that key personnel are notified of issues regardless of their location or time of day. Our system delivers both: bright visual indicators and audible alarms for floor-level response, plus sophisticated remote alerting with escalation protocols, customizable thresholds, and role-based notifications. Because when it comes to protecting temperature-sensitive inventory, the best approach is a multi-layered alerting strategy that leaves nothing to chance.

Reports and data storage: Should the data and reports be stored locally or in a cloud database?

When considering whether to store data and reports locally or in a cloud database for an environmental monitoring solution, the key factors are accessibility, security, and scalability. Storing data in the cloud offers the advantage of remote access, ensuring that reports and monitoring data are available from anywhere, and it can easily scale as your storage needs grow. Cloud storage also typically includes built-in backup and security features, reducing the burden of manual management. On the other hand, local storage can provide faster access times and may be preferred for situations where internet connectivity is unreliable or if stricter data control is required. Ultimately, cloud storage is often favored for its flexibility, cost-effectiveness, and the ease of maintaining regulatory compliance, especially for large-scale or multi-location operations.

What is the total number of temperature/humidity measurement points and their locations?

The total number of temperature and humidity measurement points, as well as their locations, are critical factors to ensure comprehensive monitoring and compliance in a warehouse or cold storage room. The number of measurement points should be determined based on the size of the space, the layout, and the areas most sensitive to temperature and humidity fluctuations (such as storage zones for perishable goods). It’s important to place sensors in areas that accurately represent the overall conditions of the environment, accounting for factors like airflow, potential hot/cold spots, and proximity to doors or refrigeration units. A well-distributed network of measurement points ensures reliable data collection, minimizes the risk of undetected anomalies, and helps maintain compliance with regulatory standards for environmental monitoring.

Does humidity need to be monitored in the warehouse? If so, where?

GDP does not make any firm regulations regarding humidity. In the GMP environment where open products are stored or processed, humidity must be monitored. Relative humidity plays an important role in the quality of many products as well as packaging integrity. Humidity is distributed very quickly and homogeneously within a room. It is therefore usually sufficient to monitor the relative humidity per room at a single central point. Humidity monitoring is crucial in warehouse and cold storage environments as it directly impacts product quality, safety, and operational efficiency. The primary areas requiring humidity monitoring are near entry/exit points where temperature fluctuations occur, around HVAC vents, close to water-sensitive inventory, and in corners or areas with poor air circulation where condensation may form. High humidity can promote mold growth, compromise packaging integrity, accelerate product degradation, and damage temperature-sensitive goods. For cold storage rooms specifically, monitoring humidity helps prevent frost formation and ensures proper defrost cycles. A comprehensive monitoring system should include strategically placed sensors in these critical zones to maintain optimal storage conditions and comply with regulatory requirements for environmental controls.

Have all regulated storage facilities and rooms been mapped and/or validated?

Mapping and validation of storage facilities are essential regulatory requirements that must be completed before storing regulated products. This process involves comprehensive temperature and humidity mapping studies across multiple seasons to identify hot/cold spots, areas of temperature stratification, and zones with environmental variability. Each storage area should undergo mapping during worst-case scenarios (summer/winter) and during both loaded and empty conditions. The validation protocol should document the placement of monitoring points, acceptance criteria, and duration of studies. Without proper mapping and validation, facilities cannot demonstrate consistent environmental control or compliance with storage requirements. This baseline data is also crucial for determining optimal sensor placement in your continuous monitoring system and establishing appropriate alarm limits. Regular revalidation may be necessary when significant changes occur to the facility, HVAC systems, or storage patterns.

Newsletter-Sign Up ELPRO News

ELPRO will use the information provided in this form to keep in touch with you and to send you updates and marketing information by e-mail.