Real-Time Temperature Monitoring for Cold Chain with the Latest Mobile-IoT Technology

The internet of things (IoT) is a system of interrelated computing devices (e.g., data loggers), mechanical and digital machines, objects, animals, or people that are provided with unique identifiers (UID) and the ability to transfer data over a network without requiring human-to-human or human-to-computer interaction.

Are all wireless technologies part of the IoT?

Following the definition above, the devices must have the capability to transfer the data over a network without requiring human interaction. Two characteristics determine the degree of fulfilment, whether a solution is described as IoT:

- Is the wireless technology based on a proprietary or a standard protocol? A proprietary protocol has security advantages but means that software is required.

- Is the antenna network used a private or public antenna network? Public antenna networks have the advantage to reach a much wider coverage compared to private networks.

/Real-time%20Monitoring/20200805%20IoT_ColdChain_EN.png)

Although LoRa (Low Range) would be the perfect technology for cold chain monitoring in terms of energy consumption and efficiency of protocol, it is not the technology of choice for most vendors. The reason for that is the lack of an international standard and roaming between the national providers.

From a pharma cold chain perspective, the only true IoT technology works with a standard protocol in a public antenna network.

The Communication Networks Glossary

Real-time tracking and temperature & humidity monitoring (real-time monitoring) of temperature sensitive products is a fast growing segment with new communication technologies and new terms arising often. In this glossary, you will learn current terminology and differences between communication networks.

-

GPS

-

GSM (2G)

-

GSM (3G/4G)

-

LPWAN/Mobile-IoT

/Real-time%20Monitoring/GPS_RealTimeMonitoring_400x250pxs.png)

The Global Positioning System (GPS), originally called NAVSTAR GPS (Navigational Satellite Timing and Ranging – Global Positiong System), is a satellite-based system owned by the government. GPS always consists of two elements: A special GPS-antenna, which is built into a device and a series of satellites, which is circling around the world and sending out radio waves. The GPS-Antenna inside the device is receiving signals from different satellites in reach and can now calculate the position exact position (1-5 m). GPS is a “one-way-system” – so it is not possible to “talk to the satellite” or transmit any data back over the satellite. Most mobile phone contain a GPS chip used to determine the position. GPS chips consume quite a large amount of energy. Therefore, they are not suitable for small cargo tackers operating over several months.

/Real-time%20Monitoring/GMS_2G_RealTimeMonitoring_400x250pxs.png)

The Global System for Mobile Communications (GSM) is a standard developed by the European Telecommunications Standards Institute (ETSI) to describe the protocols for second-generation (2G) digital cellular networks used by mobile devices such as mobile phones and tablets. GSM (or 2G) consist of an antenna network which is a typically installed on dedicated antenna towers along the highways and on hills but also on buildings, bridges etc. The GSM antenna network was built specifically for the mobile phone communication. Power consumption is significant (short battery-life). In many countries, the GSM (2G) and or the 3G network will be shut down since it is an old technology replaced by newer protocols.

/Real-time%20Monitoring/GMS_3G_4G_RealTimeMonitoring_400x250pxs.png)

Today, new standards have been set by 3rd Generation Partnership Projects (3GPP), a global consortium of seven national telecommunication standards organizations. They include third-generation (3G) UMTS standards, followed by fourth-generation (4G) LTE Advanced standards. They are both mobile communication standards and used as terms to describe the antenna networks and systems provided by telecom companies. Compared to 2G, 3G/4G networks are better suited for large amounts of data (smartphones used for internet access and consuming videos) at the same time using less battery.

/Real-time%20Monitoring/LPWAN_RealTimeMonitoring_400x250pxs.png)

LPWAN also called “Mobile-IoT” is a secure operator managed IoT network in a licensed spectrum, defined by 3GPP. The two protocols LTE-M (for mobile applications) and NB-IoT (for deep penetration into buildings) are designed for the "Internet of Things" (IoT) applications that are low cost, use low data rates, require long battery lives and often operate in remote and hard to reach locations. LPWAN networks are not suitable for Smartphone, voice and access to internet. They are often rolled out in parallel to the 4G networks and will be used in the coming years by billions of devices communicating over the IoT in all kinds of applications.

Cost Efficiency

LPWAN is an international standard where many companies are investing. Microchip manufacturers have set-up chip platforms continuously developing. Telecom and network companies are rolling-out an international network with roaming contracts. Competition and economies of scale are bringing down cost of the components and the communication/roaming – resulting in lower cost compared to previous technologies.

Low Power

Devices using LPWAN have two protocols included, both optimized for the respective purpose: LTE-M for mobile applications moving around, and NB-IoT for stationary applications. Both protocols are designed to save energy and result in much longer battery lives than traditional tracking and real-time monitoring devices.

LTE-M and NB-IoT – One Device, Two Protocols

Mobile-IoT devices using the LPWAN technology have two protocols included:

- The LTE-M protocol is optimized for “moving” applications – so a data logger or tracking device which is continuously changing its position. One of the main strengths of this protocol is the optimized antenna handshake resulting in reduced power consumption compared to other protocols.

- NB-IoT is optimized for stationary applications – so data loggers included in a warehouse, refrigerator or cellar. Besides using very little energy for the communication, this protocol results in deep penetration.

The devices can typically be pre-programmed to be in either one or the other protocol (depending on the application and country) or can also switch between the two protocols during operation.

*2G was shut down in many countries in 2020

/Real-time%20Monitoring/IoT_LT-M_NB-IoT_EN_600x400pxs_2.png?width=600&height=400&name=IoT_LT-M_NB-IoT_EN_600x400pxs_2.png)

The History of Real-Time Temperature Loggers

When talking about real-time monitoring temperature loggers we leave out all wireless technologies with proprietary antennas but only focus on battery-driven data loggers operated in a public network. In the modern logistics world, real-time tracking of trucks, ships and containers has become popular with the international rollout of the GSM network. Early devices using the GSM (2G) network had three problems:

- High battery consumption resulting in bulky devices and short battery life

- Lack of standardization in roaming and SIM-card handling

- Lack of an international standard for airline approvals

As a result, those devices were dedicated to a local trucking market or to the maritime market transmitting values from ocean containers to proprietary antennas on ships. One of the first companies to launch a true international real-time temperature and position logger was a freight express company operating a fleet of aircrafts. The price for one device was higher than 1000 USD per device – not including the connectivity and roaming.

Later devices used the 3G/4G network, which meant a significant reduction of battery consumption. Powered by lithium batteries, they achieved a battery life of 30 or more days. To get airline approval, they had to be multi-sensor devices monitoring all kinds of parameters like pressure, acceleration and light. Using lithium batteries (other than button cells) however resulted in a new problem. In 2017, IATA released a new regulation limiting the number of lithium cells per handling unit and also requested declaration of each data logger sensor used in a shipment. This was a draw back again and one of the reasons why real-time temperature loggers did not break through so far.

LTE-M and NB-IoT – One Device, Two Protocols

Proactive Intervention

With real-time temperature & humidity data loggers, Logistics Service Providers (LSP) can perform proactive intervention services knowing in the moment a temperature outside specification is measured, where exactly the product is. Compared to classical (offline) data loggers, this will result in less waste of stability data and product loss.

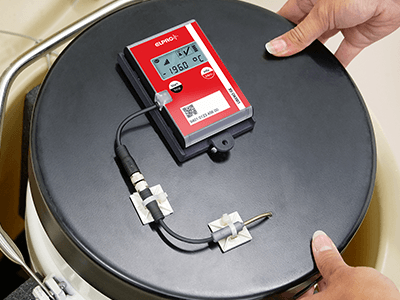

Automation

Processes at sender and recipient can be automated (automated start, automated stop, automated upload). Error-prone processes turn to robust, safe and reliable processes. All data is available 100% online without the need to retrieve data loggers, install software or train personnel in uploading files.

Asset Tracking

Using real-time temperature & humidity monitoring sensors providing temperature/humidity and position in the same device, offers new opportunities in asset tracking. Logistics Service Providers can offer a higher service level (proactive intervention) resulting in less stability budget waste and product loss. Furthermore, they can use available information to manage fleets more efficiently.

PDF Data Loggers vs. Real-Time

Market Authorization Holder (MAH) of time and temperature sensitive biologics have a need to monitor one shipment or multiple steps in the supply chain. So far, they have typically solved this by using PDF data loggers – a proven low cost technology to monitor temperature during cold chain shipments and document the release decision. When considering real-time, the following pro’s and con’s must be considered:

/Real-time%20Monitoring/PDF%20datalogger_570x300pxs.png)

PDF data loggers

- Timing of intervention: Reactive – A deviation is only found after a shipment has taken place (no proactive actions possible)

- Safety and reliability: Start and stop time stamp must be set manually (usually by button), loggers must be retrieved from handling unit and upload performed manually. Manual processes are error-prone.

- CAPA from big data: Database can aggregate the available data (including temperature, origin and destination), however there is no full visibility on the places (where has the shipment been, when the deviation happened?).

- Structure and cost: PDF data loggers are available as single-use devices at less than 20 USD in large quantities. Within the same company, they can be used in many different ways adapting to the specific process (e.g. with or without database).

Technical Failure During Shipment

- Timing of intervention: Proactive – Logistics Service Provider (LSP) is notified before a deviation happens. This will result in less waste of stability data and reduce product loss.

- Safety and reliability: Processes at sender and recipient can be automated (automated start, automated stop, automated upload). Error-prone processes turn to robust, safe and reliable processes.

- CAPA from big data: The performance of the logistics service providers get visible. Aggregated temperature and position data can be used to improve the cold chain and reduce cost (heat-maps, insurance cases).

- Structure and cost: Real-time data loggers are (still) significantly more expensive than PDF data loggers and need a more structured/central/uniform approach since all configuration and evaluation takes place in the central database.

Working with PDF data loggers and sensors has the advantage of low-cost hardware allowing flexible set-ups. When using real-time data loggers for cold chain monitoring, the shipper gets in control, getting rid of unreliable manual processes and can continuously improve the cold chain. MAH will choose a mixed approach shipping the less critical products on less risky trade-lanes with PDF data loggers and using real-time devices on the rest.

Position Precision of GPS vs. Triangulation

Dedicated GPS chips are guidance systems, supporting your car navigation through traffic and supporting your smartphone apps if they need to know the exact position. GPS chips determine the position using satellite signals and in the ideal case, can provide accuracy of less than one meter. However, the downside of GPS, is it’s relatively expensive and consumes a lot of power.

The alternative method of tracking the position is cell tower triangulation of the available network antennas. Depending on the number of antennas the specific device has in its reach, the accuracy of the position can be 2 kilometer or 10 meter.

Research with cargo logistics companies tracking assets, as well as with pharmaceutical companies shipping highly sensitive and valuable goods, have shown that accuracy of the position is not a highly relevant factor. Why?

- Using the position for early intervention: Supply chains are complex and often include many different steps and service providers. It is less important to know exactly where the shipment is (in coordinates precise to a pallet position) than to have an escalation process to the right employees at the right place (Swisscargo in Chicago, phone number xyz) since they will know themselves where exactly they hold the pallet or container in trouble.

- Using the position for taking actions on geo-fences: State-of-the-art tracking and real-time monitoring solutions have the capability to use geo-fences as triggers, like setting the start or stop time stamp, or sending a notification if it leaves a defined place. It is sufficient to know “it has arrived at destination warehouse” – we don’t need to know at which exact ramp the truck is unloading.

- Using the position for heat-maps: Big data consisting of billions of datasets from thousands of shipments taking place along the same routes can be used for generating heat maps. For example, what is the airport where the most temperature deviations occur? Again, this is not a question of the exact position. An approximate position from a triangulation is good enough.

- Using the position for insurance cases: In case of a major deviation, the product owner might be ultimately faced with an insurance case. The main question is “In who’s custody was the product, when the error happened”? This is a question of time and position. In most cases, a triangulated position is by far strong enough.

Security to Consider in a Public Mobile-IoT Network

Whatever technology is used to collect temperature data from data loggers used to monitor shipments: some sort of hard- and software will be used which is outside your direct control. No matter if you work with a PDF device where a computer is used to generate and upload the PDF report via a mail-system or browser upload, or if you work with a real-time device connecting to a public antenna network: by definition, data flows through antennas, computers, servers and “the internet” before it arrives safely in the cloud. Important – irrespective of the chosen solution – to assure data integrity.

/Real-time%20Monitoring/RealTime_Data%20Integrity.png)

For real-time devices working with a public network, the security efforts start with designing the devices at maximum security levels including encryption. In addition, the network provider can encapsulate the data stream via IPsec (Internet Protocol Security) tunnels or MPLS (Multiprotocol Label Switching). In this way, the public network becomes a quasi-private network and enables a secure connection in a shared infrastructure with logical domains. The most important security measure however is the confirmation: only after confirmation that the data has arrived in the Cloud with the right checksum, the data logger will “hook-off” the communication package – otherwise it will keep on pushing the data again in its original form.

Applications of Real-Time Data Loggers

-

Cell and Gene Therapy

-

Asset Tracking

-

Global Supply Chain

-

Clinical Supply Chain

Cell and Gene Therapy High Risk Shipments

When shipping high-value time and temperature sensitive biopharmaceuticals, temperature and time is of essence. Due to the high value of the products, loss of product due to temperature deviations is not an option.

Requirements to real-time tracker:

- Compliance in temperature monitoring

- Zero deviation due to real-time intervention

- Combine real-time device with classical PDF data logger for less critical products/shipments

Asset Tracking and Compliance

Logistics service providers owning and operating fleets of cold chain equipment (containers, multi-use boxes, trucks & vans) must provide compliant temperature monitoring at the same time have the need to increase utilization on their valuable assets. So far, those two tasks have been typically separated by using logistics trackers for the position and separate validated temperature monitoring data loggers (placed by the shipper or sometimes offered as an ad-on).

Requirements to real-time tracker:

- Monitor temperature and position

- GAMP 5 validated

- Battery life of >1 year

- Integrate to own asset management solution

Global Supply Chain Visibility and Insights

Many large pharmaceutical companies have a mixture of products, shipping modes and packaging methods. Shifting all their monitors from PDF to real-time is not an option for cost and complexity reason. They want a temperature monitoring database which offers all options in parallel: Real-time trackers, PDF data loggers, low-cost box-level indicators.

Requirements to real-time tracker:

- Real-time capabilities with global visibility and control

- Compliance in temperature monitoring

- Combine real-time device with classical PDF data logger for less critical products/shipments and box-level indicators

- Simple and intuitive to use

Global Supply Chain Visibility and Insights

In particular clinical trials are often shipped to remote destinations where the responsibility for the product is not handed-over to a customer or recipient but it remains with the product owner. In such situations, data loggers with a battery-life of up to 2 years are used to monitor the shipment, release the product at destination and follow the product into the local storage or refrigerator. The data archive and alarming must be under central control.

Requirements to real-time tracker:

- Monitor products during shipments

- Safe and easy release at destination

- Follow the product into remote warehouses and refrigerators

- Keep on monitoring the product during storage at remote site

Contact Our Real-Time Monitoring Consultants Today

Newsletter-Sign Up ELPRO News

ELPRO will use the information provided in this form to keep in touch with you and to send you updates and marketing information by e-mail.